Dye-Sublimation Printing Technology for your Exhibition Graphics

As an exhibitor, at times, you must be facing issues while understanding all the technical terms that your exhibition stand design company might be using while explaining about creating effective exhibition graphics. You don’t need to have a complete knowledge of the technology used by your exhibition company, but a basic understanding of the technology accessible and the graphics creation process would be helpful. There are several types of large-format printing technologies which involve latex printing, solvent technology, aqueous printers and many more.

Out of all of these, the most beneficial and rapidly growing segment of large format graphic printing is dye-sublimation. According to the latest research, Dye-sublimation technology has statistically risen and is estimated to print over 1.54 billion sq.m of material in 2018. Now, many of us do not have a clear idea about this printing technology. So, before we begin talking about the benefits of this technology, let’s just first understand what exactly is dye-sublimation technology?

What is Dye-Sublimation?

Sublimation is a phenomenon through which certain substances are changed from solid to gas state directly. Using Dye-sublimation printing in your exhibition graphics involves heating ink to turn it into gas. This allows attaching the dye permanently to the dedicated surface providing bright colours and high-resolution images. This process works best on polyester and polymer-coated substrates.

With advancements in print technology paving way for visual merchandising and marketing creativity, Dye-sublimation has become the most preferred imaging method for exhibition stand graphics. This cutting-edge printing method provides rich colour saturation and enhances the efficiency in shipping and installation process. A Dye-sublimated material captivates light and makes your image anti-reflective. It is an environmentally friendly process, as the ink used is made from aqueous solutions which are solvent-free and fragrance-free.

How Dye-sublimation benefits Exhibitions

Having a dye sublimation printing process for your exhibition graphics help in consistently producing a high-quality product. This helps in making your brand messages and marketing initiatives bolder, brighter and more effective. Below are a few advantages of using a dye-sublimation printing technology in your exhibition stand graphics.

Long-Lasting:

The dye is permanently imprinted on your fabric as the chemical bonding of the ink with the lenient material makes the printing process of your exhibition stand design extremely durable. These prints are as good as traditional graphics and are easily accessible. They are not delicate like laminated ones and are easily washable.

Visually Appealing:

It has been observed that the matter printed with the dye-sublimation method set forth images distinctly superior to other printing processes. The dye-sublimation technique imparts a constant flow of colour instead of distinct pixels as categorized by inkjet printers. Due to this, the exhibition graphic design images have sharply defined edges and appear clearer and brighter.

Supreme Quality:

A dye sublimation graphics printing method steadily creates a superior product. It enables you to make your brand messages and marketing initiatives to be bolder, livelier and more effective. The dye used in the process merges well with the fabric. This results in having smoother colours with more variant and better conversions. Exhibition graphics printing that uses dye sublimation ink offers excellent contrast and intensity. The colours appear vibrant and presented in an extensive range at high density.

Lightweight & Foldable:

Apart from being durable and long lasting, dye sublimation fabric is also travel-friendly. Even a large foot graphic print can be easily folded down to the smaller size and weighs hardly any pounds. With such size and weight, it can be inexpensively transported and be packed in a suitcase. Moreover, the lightweight requires less fuel and energy to transport, making it more eco-friendly.

Anti-Reflective:

Exhibition stand graphics printing which uses dye-sublimation technology serves as a great source to depict your brand message clearly. The dye-sublimated fabric used for your graphic print can absorb light and is capable of preventing reflections from appearing on your graphic image. This ensures that your exhibition stand graphics are distinctly visible across the exhibition hall without any distortion.

Versatile:

Dye-sublimation printing technology works great for both indoor as well as outdoor exhibition graphics. A thin line of silicone around the edges of your printed fabric helps in the easy mounting of the fabrics. You don’t have to hire a separate crew to install new exhibition graphics thus making the process user-friendly.

Cost-Effective:

The Dye-sublimated printed material is lightweight compared to the traditional rigid materials, which make it easily transportable. Reduced weights results in diminishing the shipping costs of your exhibition graphics compare to the other printing processes. This fabric can be folded enabling it to use less space and thus can be stored and shipped at a much lower cost.

A Dye-sublimation printing is exclusively used with material that is lightweight, easy to handle and relatively inexpensive. It offers exhibitors great flexibility in terms of graphic forms. Hope this article helped you get a fair idea about dye-sublimation prints and how they can be a practical solution for your exhibition needs. You can always ask your exhibition stand contractor if they are using dye-sublimation printing technology to make exhibition graphics.

About Expo Display Service:-

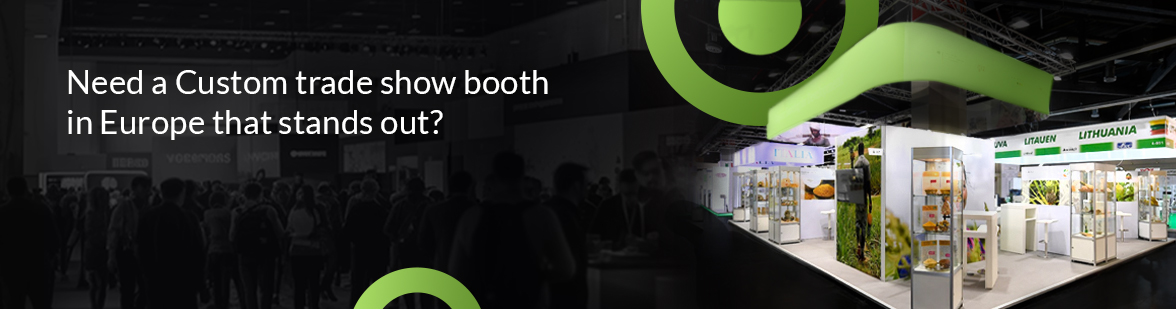

Expo Display Service has over 3 decades of experience in exhibition stand designing and construction, making it your most reliable exhibition partner in Europe.

We have the largest online catalog on exhibition stand designs! With just 3 clicks on our Expo Stand Configurator get your perfect match!